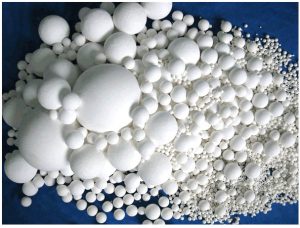

Alumina ceramic ball / inert ceramic ball

Inert ceramic balls with high strength, high chemical stability and thermal stability characteristics, it can be high temperature, high pressure and acid, alkali, salt and various organic solvents, corrosion, widely used in petroleum, chemical,

Fertilizer, natural gas and environmental protection industries. As a catalyst in the reactor support and covering material. Buffer into the reactor liquid and gas impact on the catalyst to protect the catalyst, and change

Good Reactor liquid and gas distribution

| chemical composition | AL2O3 | 20-70 |

| AL2O3+SIO2 | ≥90 | |

| Fe2O3 | ≤1 | |

| Water absorption (%) | ≤3 | |

| Acid resistance (%) | ≥98 | |

| Alkali resistance (%) | ≥80 | |

| Resistant to alkalinity heat temperature (℃) | ≥1300 | |

| Compressive strength N / pcs | Ф19 | ≥1800 |

| Moh’s hardness | ≥6.5 | |

| dulk density kg/m2 | 1300-1400 | |

Specification : Φ3mm-Φ100mm.

Chemical packing balls

|

Specification

|

Medium Alumina

|

Medium-high Alumina

|

High Alumina

|

99%-Alumina

|

||||||

|

ceramic ball

|

ceramic ball

|

ceramic ball

|

Ceramic Balls

|

|||||||

|

Al2O3(%)

|

40-45

|

70-80

|

90-92

|

99

|

||||||

|

Water Absorption (%)

|

<1

|

<1

|

<1

|

<1

|

||||||

|

Crush strength KN/particle

|

φ3

|

﹥0.2

|

>0.4

|

>2.0

|

>2.0

|

|||||

|

φ6

|

﹥0.5

|

>0.6

|

>5.0

|

>5.0

|

||||||

|

φ13

|

﹥1.4

|

>1.5

|

>8.5

|

>8.5

|

||||||

|

φ19

|

>2.9

|

>3.0

|

>12

|

>12

|

||||||

|

φ25

|

﹥3.5

|

>4.5

|

>16

|

>16

|

||||||

|

φ38

|

﹥5.0

|

>5.9

|

>23

|

>23

|

||||||

|

φ50

|

﹥6.3

|

>8.5

|

>34

|

>34

|

||||||

|

φ76

|

﹥8.9

|

>14

|

>47

|

>47

|

||||||

|

φ100

|

﹥11.0

|

>18

|

>56

|

>56

|

||||||

|

Bulk Density (Kg/m3)

|

1400-1500

|

1500-1800

|

1800-2200

|

1800-2200

|

||||||

|

Specification

|

Medium Alumina

|

Medium-high Alumina

|

High Alumina

|

99%-Alumina

|

||||||

|

ceramic ball

|

ceramic ball

|

ceramic ball

|

Ceramic Balls

|

|||||||

|

Al2O3(%)

|

40-45

|

70-80

|

90-92

|

99

|

||||||

|

Water Absorption (%)

|

2-5%

|

2-5%

|

2-5%

|

2-5%

|

||||||

|

Crush strength KN/particle

|

φ3

|

>0.15

|

>0.15

|

>0.2

|

>0.2

|

|||||

|

φ6

|

>0.4

|

>0.4

|

>0.5

|

>0.5

|

||||||

|

φ13

|

>1.5

|

>1.5

|

>2.0

|

>2.0

|

||||||

|

φ19

|

>2.0

|

>2.5

|

>3.0

|

>3.0

|

||||||

|

φ25

|

>3.0

|

>3.5

|

>4.0

|

>4.0

|

||||||

|

φ38

|

>4.5

|

>5.0

|

>5.5

|

>5.5

|

||||||

|

φ50

|

>6.5

|

>7

|

>9.0

|

>9.0

|

||||||

|

φ76

|

>11

|

>12

|

>19.0

|

>19.0

|

||||||

|

φ100

|

>14

|

>17

|

>22.5

|

>22.5

|

||||||

|

Bulk Density (Kg/m3)

|

1400-1500

|

1500-1800

|

1800-2200

|

1800-2200

|

||||||

High purity alumina ceramic ball

High purity alumina ceramic ball / corundum ceramic ball

Widely used in petroleum, chemical, natural gas, environmental protection and other industries, as the catalyst support covering the reactor material, its main role is to increase the gas or liquid distribution points, support and protection of low activity catalyst.

High purity alumina ceramic ball / corundum ceramic ball Features:

1, high purity Alpha alumina structure and low content of silica

2, good heat resistance and mechanical impact resistance

3, good chemical stability

Application range

Desulfurizer Dehydrogenation Catalytic reforming Catalytic isomerization Ethylene cracking and drying polymerization Low temperature conversion High temperature conversion Methane conversion

Naphtha reforming Methanol and hydrogen production

Chemical composition

| chemical composition | 90% caramica ball | 99% caramic ball | 99.5% caramic ball |

| Al2O3 | >90% | >99% | >99.5% |

| SiO2 | <7% | <0.2% | <0.15% |

| Fe2O3 | <0.5% | <0.1% | <0.1% |

| Na2O+K2O | <1.0% | <1.0% | <0.4% |

| MgO+CaO | <1% | <0.2% | <0.2% |

Specification:

| Item | 90% inert caramic ball | 99%-1 inert caramic ball | 99%-2 inert caramic ball | 99.5% inert caramic ball | |

| The max working temperature | 1500℃ | 1500℃ | 1600℃ | 1600℃ | |

| Water absorption | <5% | <2-6% | <1% | <1% | |

| specific weight | ≥3.1g/cm3 | ≥3.3g/cm3 | ≥3.65g/cm3 | ≥3.68g/cm3 | |

| Dulk density | ≤38mm | 1.8kg/L | 2.0kg/L | 2.0-2.16kg/L | 2.0-2.16kg/L |

| 50mm | 1.6-1.7kg/L | 1.9-2.0kg/L | 2.0kg/L | 2.0kg/L | |

| 70mm | 1.6kg/L | 1.9kg/L | 1.9kg/L | 1.9kg/L | |

| Moh’s hardness | 9 levels | 9 levels | 9 levels | 9 levels | |

| Impact resistance (free fall from 6 meters off 25mm thick steel plate without broken) | pass | pass | pass | pass | |

| Single compressive strength (kN) | 3mm | 0.4 | 0.5 | 0.6 | 0.6 |

| 6mm | 1.3 | 1.5 | 1.6 | 1.6 | |

| 10mm | 5 | 6 | 6 | 6 | |

| 13mm | 7 | 8 | 8 | 8 | |

| 16mm | 15 | 9 | 13 | 13 | |

| 19mm | 17 | 18 | 19 | 19 | |

| 25mm | 22 | 20 | 22 | 22 | |

| 38mm | 35 | 37 | 40 | 40 | |

| 50mm | 40 | 42 | 45 | 45 | |

| 76mm | 50 | 55 | 60 | 60 |

We can produce inert caramic ball according customers requirement.

Welcome your inquiry us carrier@catalystcarrier.net